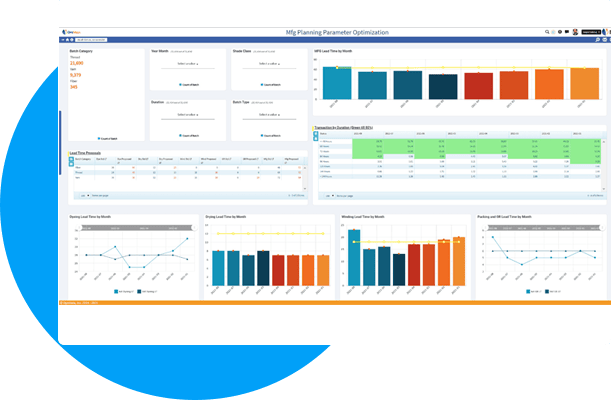

Actions Enabled

- Updates to forecasts

- Updates to procurement/production plans

- Updates to planned inventory mix

- Updates to planning parameters

Beyond showing data, OpsVeda continuously validates plans, identifies forecast risks,

and alerts stakeholders to supply-demand gaps before they escalate.

Operational plans are cross-functional and must accommodate conflicting priorities. Visibility is only part of the solution. The bigger challenge is inter-departmental optimization. Complex processes that change often and a very uncertain business environment add to the difficulty.

OpsVeda continuously assesses the realness of plans by evaluating forecasted demand as well as the ability of planned supply to service the demand. Potential forecast problems and supply-demand misalignments are detected early, and stakeholders are alerted. In many cases preventive or corrective actions are also prescribed.

2%

20%

3%

15%

Get clear pricing, plan details, and answers from our team.